Buttons and keyboards of the machinery used in the food and medical sectors have common technical needs. They must be easy to sanitize, not accumulate dirt, be reliable and resist degradation despite the stress they are subjected to. These requirements must, whenever possible, coincide with an intuitive design.

Although today it is the most used solution to realize these user interfaces, mechanical buttons made of plastic or metal, have very strong limits on all the specifications listed above. They accumulate dirt, wear out quickly and are not easy to clean.

In addition, the focus on developing products that are easy to sanitize has increased exponentially in recent years due to the health risks associated with the Covid-19 pandemic. The need to develop products that can be easily sanitized has extended to products in common use such as household appliances.

The possible solution could be combining intuitive and functional touch technology for the creation of buttons and switches with glass, durable and easy to sanitize.

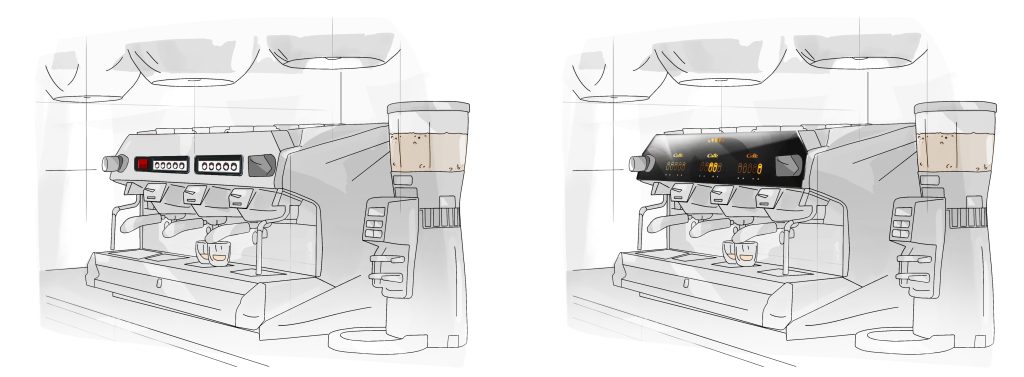

A comparison between mechanical buttons and glass touch keypads.

One of the main characteristics of glass is having a very low porosity. This property allows it not to absorb and not to release substances. The glass avoids the accumulation of dirt residues after cleaning the surface, resulting in an excellent material to be sanitized easily.

There are many research studies (example) dedicated to the development of glasses that integrate antibacterial properties, obtained thanks to surface treatments or mix of materials of which they are composed.

Moreover, glass is an extremely robust material capable of maintaining its mechanical properties even when stressed. Surely the operating life cycle of a product with glass surfaces is much greater than the plastic surfaces themselves.

In addition, touch technology is the trend of the near future for the creation of buttons and keyboards. Touch systems have considerable design advantages but they are not the only benefits that they bring to the product in which they are integrated.

There are also fundamental technical benefits that make touch technology the new frontier for sectors such as food and medical or in general all products that need simple sanitation.

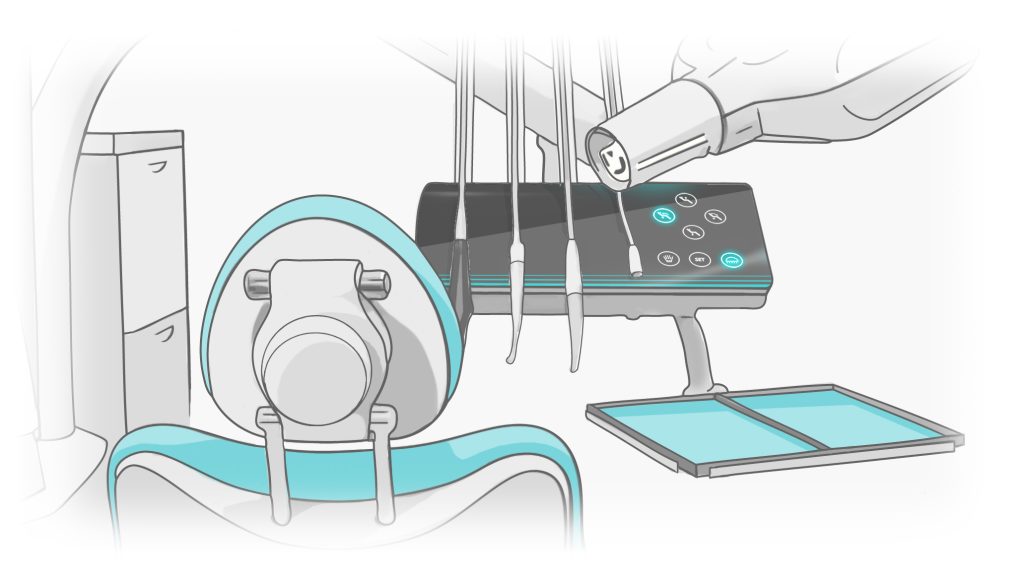

Example of touch keyboard inserted in the medical field.

Another fundamental aspect is that in touch keyboards the surface of the keyboard remains continuous, without the coves necessary to build the mechanical buttons that inevitably lead to accumulation of dirt.

The touch technology combined with glass has all the necessary advantages for the realization of innovative products with keyboards easy to clean and sanitize.

To these technical characteristics are added the greater durability and resistance compared to plastic materials that combine with aesthetic advantages given the higher and more intuitive design of glass touch buttons than mechanical ones.

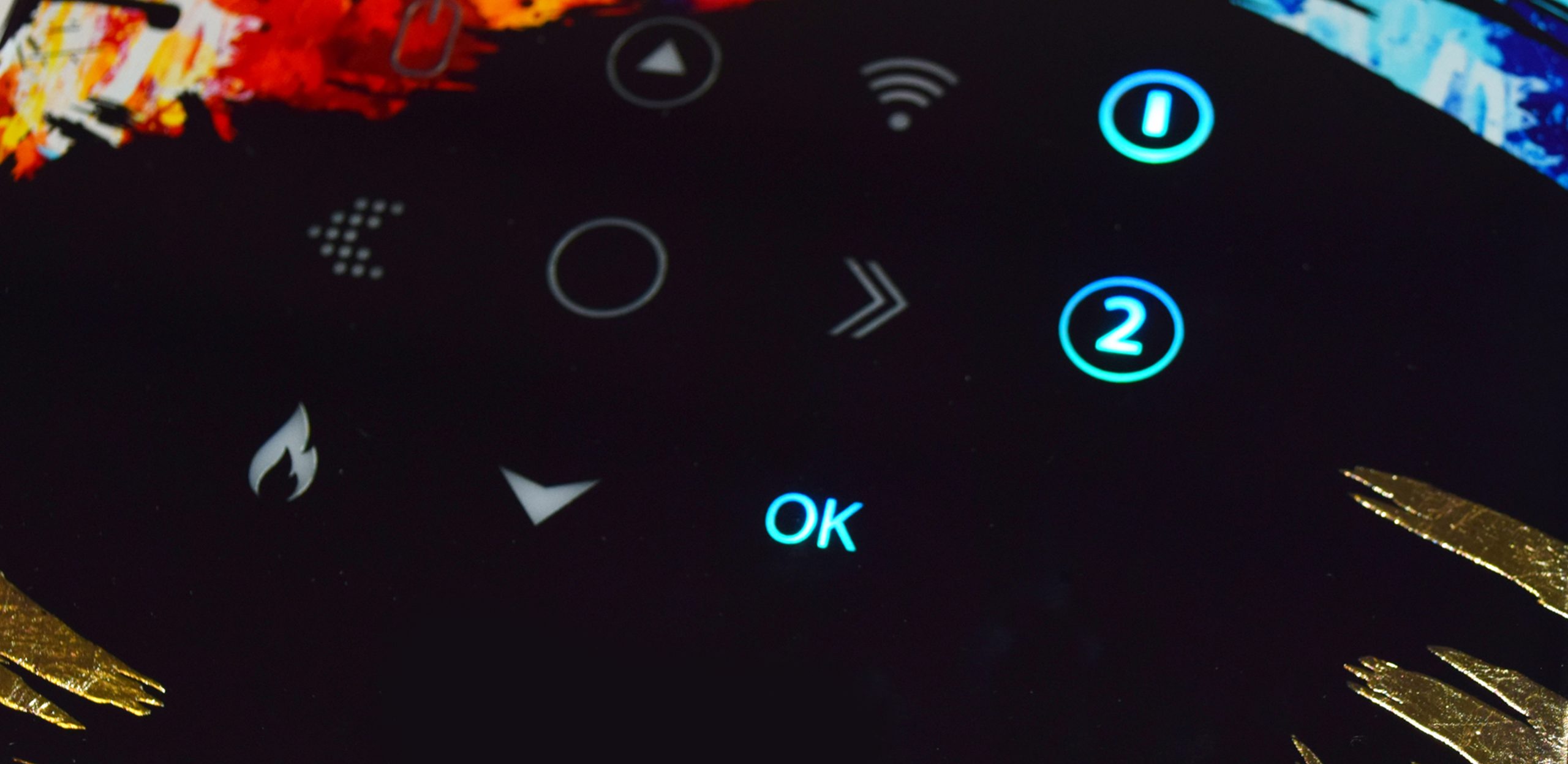

èlevit is an innovative start-up that has developed highly reliable and fully customizable glass touch buttons and keyboards that can be integrated into medical and food machinery, combining the need for hygiene and sanitization with excellent technical functionality.

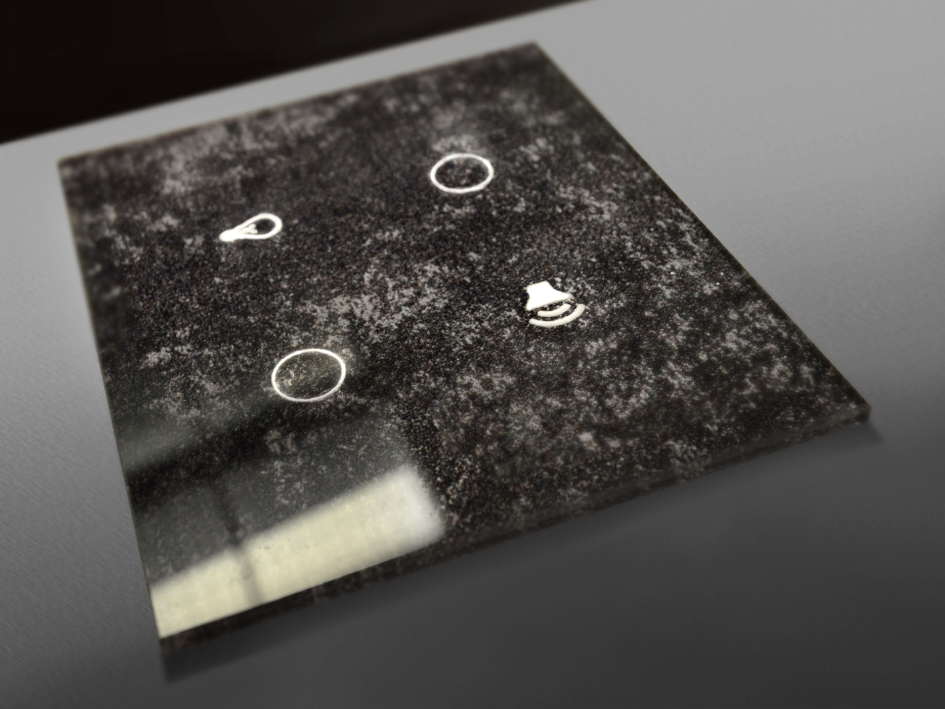

An example of glass touch keyboards produced by èlevit.